Circular Design

Starting at the Design Stage

Circular Design considers material choices and influences the way products or services interact with people and everyday systems such as logistics, collection, and end of life disposal. It’s estimated that over 70% of a product’s environmental footprint is determined during its design phase. Circular Design informs Circular Business Models by reducing over-specification, and taking into account the environmental impact over the course of the full the lifetime of the product or service.. By designing items for extended use the emissions embedded are spread-out and reduced over time.

WOOL

Employing the strength of natural fibres

Wool has the potential to replace other more carbon intensive materials based on understanding the environmental impact versus performance needs of the specified material. Circular design for wool uses regenerative materials and keeps textiles in use providing pathways for reuse, recycling and end-of-life solutions. Wool, which is composed of keratin protein and one of the strongest natural materials on the planet, follows a natural biodegredation process, and yet can be used in many technical applications, including construction, packaging, agricultural as well as the more familiar textiles for seats, carpets and insulation. To be fully circular, items made of wool feedstock would be blended with only natural materials, designing out things such as synthetic polymers, additives, chemicals and coatings that add costly challenges to efficient recycling or end of life options.

Click here to read the Wool Innovation Action Plan.

Listen to what the experts say regarding Wool and its potential as a circular product.

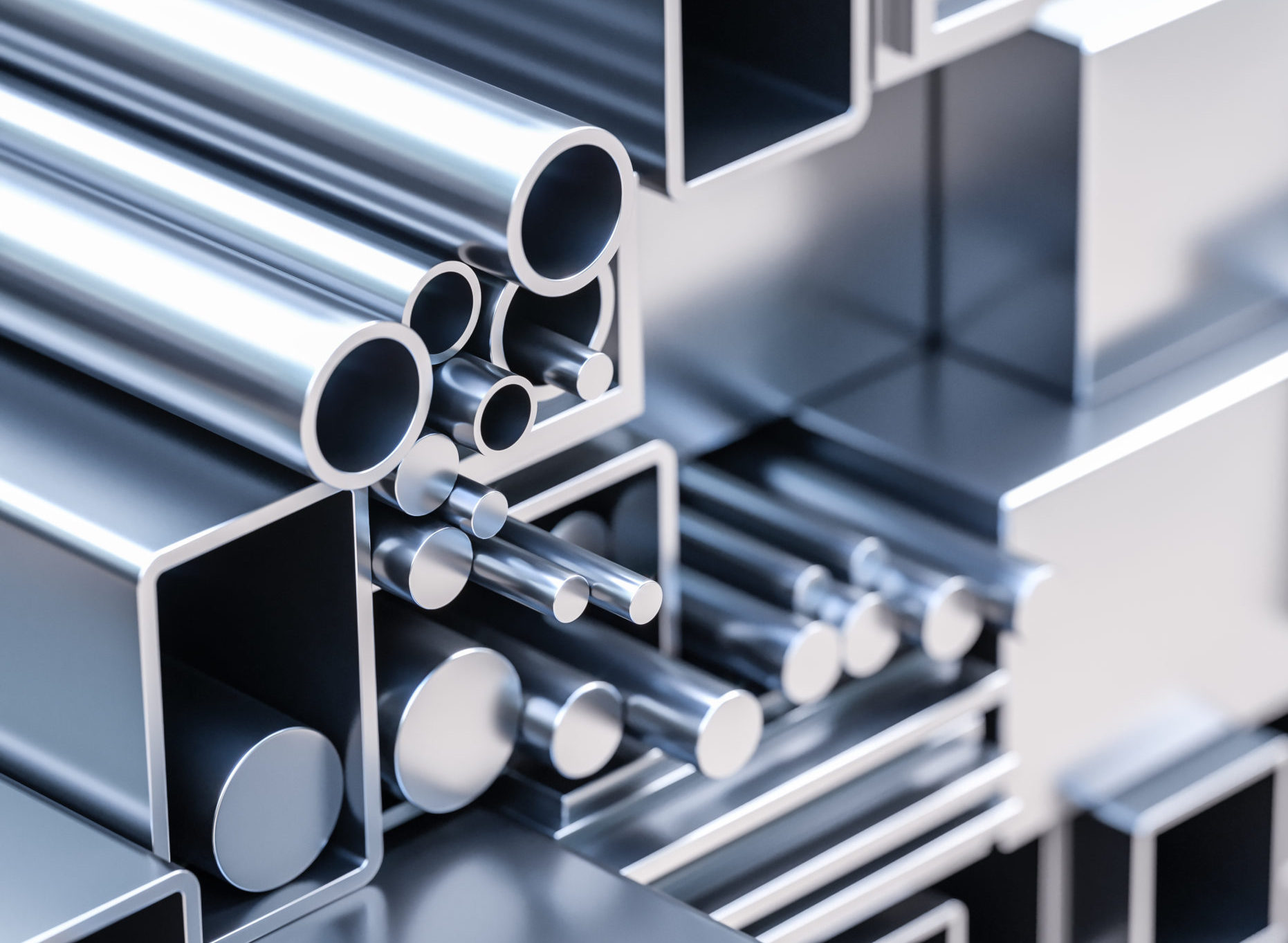

ALUMINIUM

Retaining the value

As we work to achieve Net Zero, Aluminium has an important role to play in due to its lightness, conductivity, formability, and durability. Designing aluminium products, in a way that enables efficient dismantling after use can lead to further reductions in environmental impact. Design for disassembly in aluminium context means de-constructing items into component parts and reclaiming those that are suitable for reuse, while distributing the rest into other sustainable end-of-life scenarios. This is particularly important for high demand metals. For example, using aluminium to achieve a 10% reduction in vehicle weight can result in around 8% of fuel economy. In order to mitigate the carbon footprint in supply chains, leading car designers are now working to build closed loop production facilities where car parts are made from aluminium taken out of previously discarded vehicles.

Click here to read the Innovation Action Plan for Aluminium in a Circular Economy.

CHEMICALS

Transforming Industrial Waste Gases to Chemicals

As we look towards building global resilience and competitiveness, we must find ways of establishing UK manufacturing supply chains that provide products without having a negative impact on our environment. Through Carbon Capture and Utilisation (CCU) of industrial waste gases (CO and CO2), we can produce higher-value, lower carbon-footprint chemicals and products that reduce our reliance on fossil fuel feedstocks. A recently published Innovate UK Business Connect Catalysis Innovation and Net Zero study highlights that CCU, coupled with renewable energy, low carbon hydrogen and Power-2-X technologies, presents a significant opportunity to manufacture chemicals in the UK with a low carbon footprint. The drive to move towards more sustainable chemicals – for example, Unilever’s commitment to replacing fossil-derived carbon with renewable or recycled carbon by 2030 – further emphasises the need for CCU.

Click here to read the Action Plan for Transforming Industrial Waste Gases (CO/CO2) to Chemicals.

Innovations in CCU need to be developed with a systems approach considering real world process conditions, from individual unit operation design through to complete processes. It will require new collaborations to be formed along the value chain to develop and establish the technical and commercially viable routes from feedstock (quality and quantity) through to final product.

Join the Circular Economy Innovation Network

If you would like to take part in the discussion and be kept updated of our activities, join our Community.